Our Profile

Roles Of A Port

Westports Malaysia plays a pivotal role in international maritime trade and Malaysia’s economic development. Below is a breakdown of those roles:

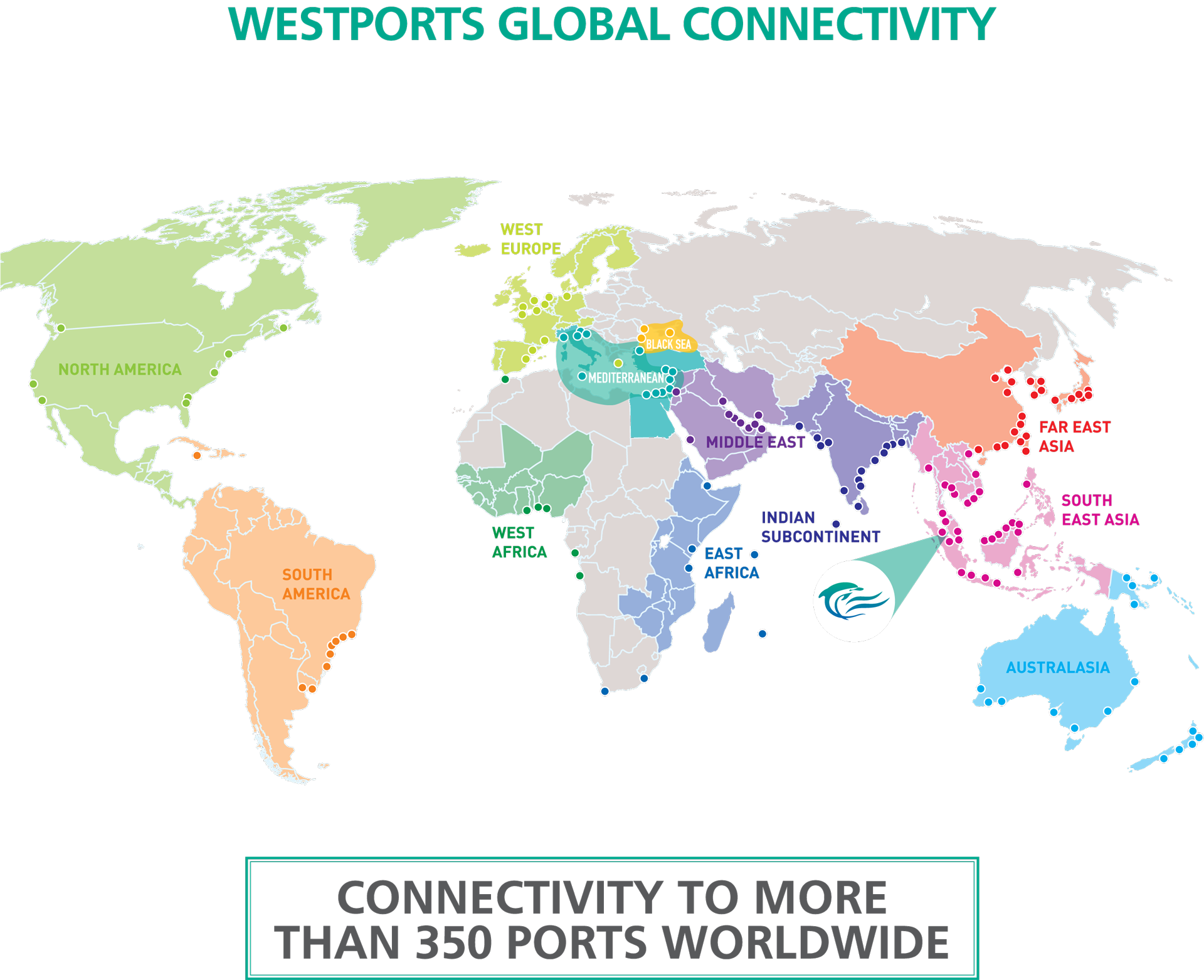

PROVIDES FAST CONNECTIVITY IN ORDER TO TRANSPORT THE PRODUCTS TO ITS CONSIGNEES

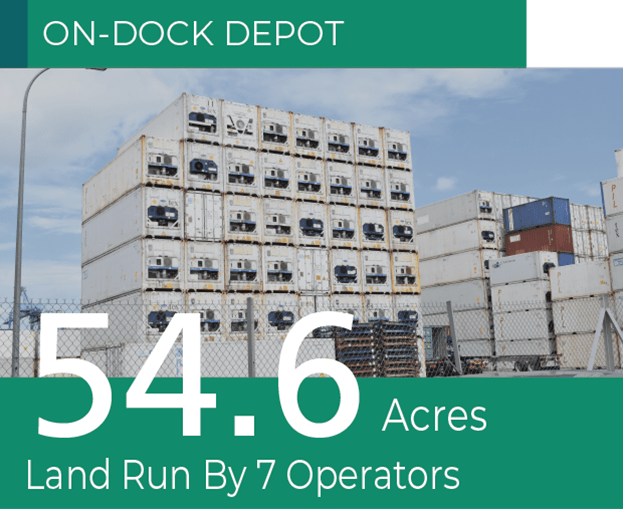

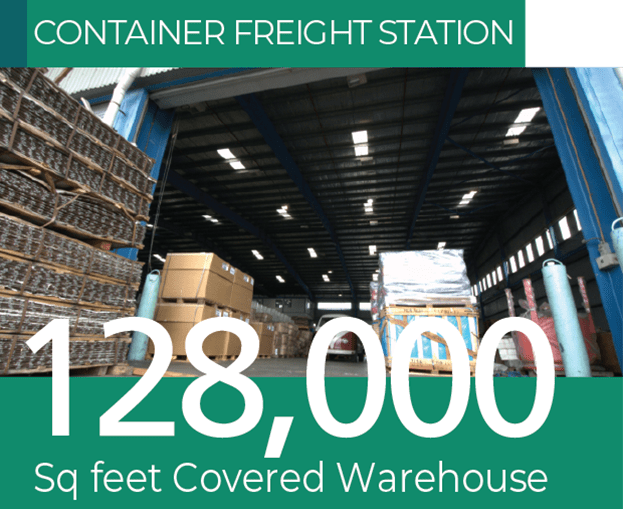

PROVIDES STORAGE SPACE & WAREHOUSING FACILITIES

PROVIDES BUNKERING AND OTHER SHIP RELATED FACILITIES

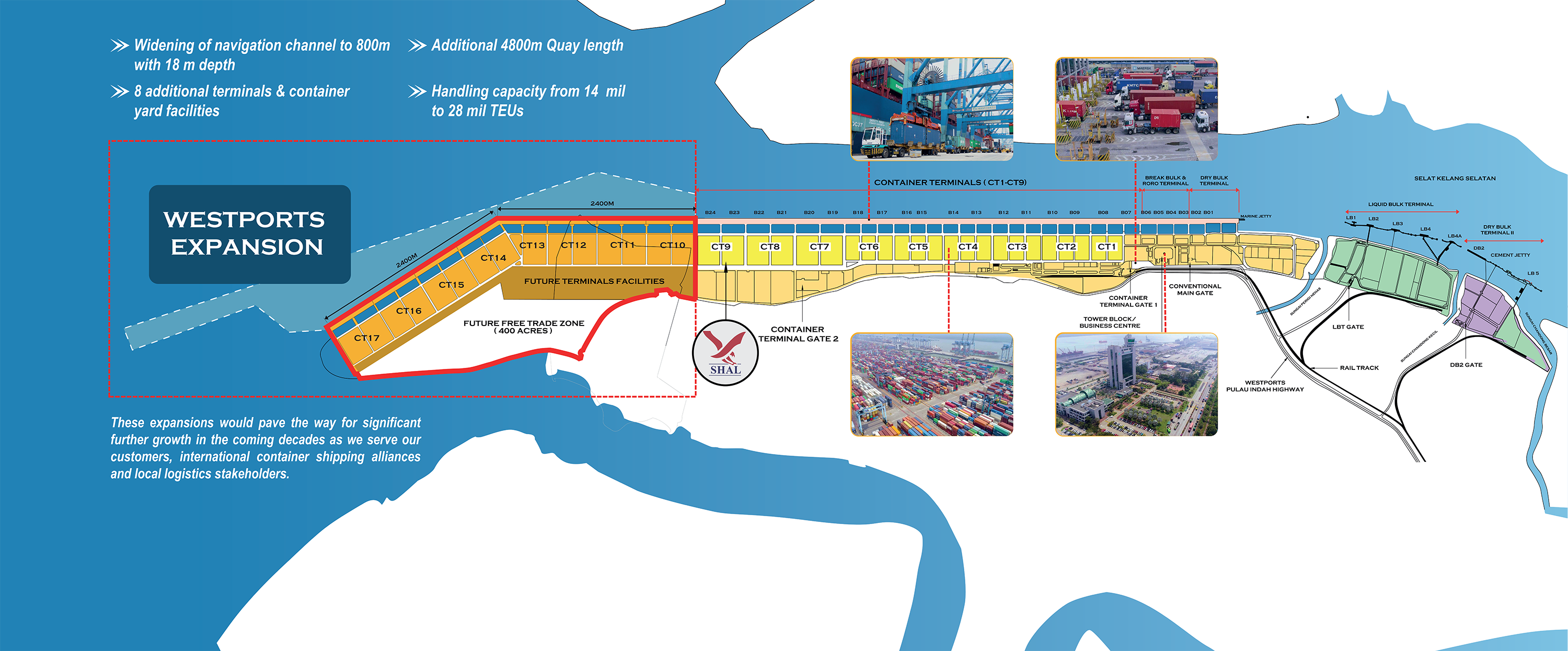

Port Layout

Value Added Services

Technology

CONTAINER TERMINAL GATE 2

In the initiative to increase productivity, Royal Customs Malaysia has also installed 3 scanners at the second gate to enable them to scan laden containers. This helps customs to reduce man power and increase time taken to check containers during the gate out process.

IT - KEY TO WESTPORTS'S EFFICIENCY

IT plays an integral and ubiquitous role in handling Westports’s operations to meet the demands of tomorrow which are increasing productivity, efficiency and capacity, while simultaneously increasing safety and security, and enhancing customer service.

CONTAINER TERMINAL OPERATING SYSTEM

AVP (Advanced Vessel Plan) and AYP (Advanced Yard Plan) provides automated ship operation and efficient use of yard space. TLS (Terminal Logistics System) is an asset management system that streamlines equipment work queue based on individual workload. These features allow terminals to minimize equipment movement, save turnaround time, increase operational productivity and reduce schedule inaccuracy.

Advanced Vessel Planning

AVP (Advanced Vessel Planning) is an automatic process planner that localizes towards each vessels’ needs. OPUS Terminal combines EDI information, container status, equipment position and workload information from equipment and vessels. By optimizing discharging/loading sequence based on this data, operators benefit from shorter turnaround time and less gap between operation and planning. Higher productivity is accomplished through reduced container re-handling in the yard and minimized un-laden traveling of equipment.

Terminal Logistics System

TLS (Terminal Logistics System) provides total management of all equipment workflow within the terminal. TLS individually assigns and balances workload for each equipment based on its condition and work queue. Coordinating equipment work process minimizes waiting time so that containers can travel from end-to-end on schedule seamlessly. Single platform managing from Gate, Vessel, Rail and to Yard process optimizes the terminal process as a whole and allows operators to respond to problems quickly.

Advanced Yard Allocation

AYA (Advanced Yard Allocation) is a container distribution platform that resourcefully distributes container movement in the yard. Containers that enter from gate are instantly arranged a place in the yard significantly reducing re-handling work. Unloaded containers from vessels are practically allocated to the yard based on QC work queue and vessel’s stowage location. AYA taking care of overall container distribution significantly decreases terminal turn time of external trucks within the terminal.

Interface Standard

OPUS Terminal is a platform solution that tightly integrates different terminal protocols into one cohesive unit. Mixture of different assets and systems often impedes terminal integrity and productivity. Under a single umbrella, terminals can be now managed with efficiency, stability and trouble-shooting.

With planning capability tightly coupled with operations which captures real-time movements within the container terminal, our overall operations monitoring, optimized equipment utilization and resource allocation enable Westports to meet the next decade’s demands in terms of productivity and increasing throughput.

TETRA

Deployed in 2008, indoor and outdoor radio communication between operation control centre and terminal equipment operators has significantly improved.

E-TERMINAL PLUS

e-Terminal which comprises of e-Berthing, e-Submit, e-SSR, e-Loading, e-Deliver Order, e-Gate Pass, e-PreArrival, e-TDR and e-Billing were developed in-house. Through e-Berthing, shipping lines can view the real time and planned vessel berthing status. With the availability of real time information, shipping lines can transparently pre-plan their berths with Westports.

Alternatively to EDI, e-Submit allows for the submission of discharge and loading information electronically via the Internet. To cater to disparate formats used by different shipping lines, the robust e-Submit data-mapping engine can map any format. Upon submission, verifications and validations are done up-front, instant corrections can be made should there be any discrepancies.

e-Special Service Request (e-SSR) provides shipping lines with the ability to manage changes on-line therefore maintaining integrity and traceability hence reducing the logistic time taken for paper-based submission.

Our integrated container terminal operations system simplifies and eliminates the submission of loading information through the e-Loading by automatically creating the loading list. This streamlined process enables vessel planning and yard planning to be commenced before the documentation cut-off time, thus leading to better efficiency and productive resource allocation.

In line with Westports’s strategic objectives to create a simplified and paperless environment, the e-Delivery Order (e-DO) system for import enables on-line issuance by shipping lines thus replacing the paper-based Delivery Order (DO).

Seamlessly integrated to Royal Malaysian Custom’s system, for release and clearance of containers and e-Gate Pass for the issuance of terminal release document, this streamlined process eliminates the use of paper-based DO and the presence of the forwarding agents at Westports.

The e-PreArrival feature enable hauliers to make appointments before collecting inbound and dropping their outbound containers with the benefits of reducing their turnaround time and waiting time.

The e-Terminal Departure Report (e-TDR) is available for shipping lines to view and download upon vessel departure. In addition to the quick dissemination of departure reports, it also acts as a centralized data repository.

The e-Billing feature enables customers to access their billing and account information on-line. It is designed and innovated in-house to cater for our customers with the purpose to streamlining and improving the billing services.

The mobile – on the go – version of the e-Terminal portal

The mobile version was officially launched on 10.09.2015 and it allows access to our customers anytime and anywhere from their smartphones. It is available for android in Google Play. The mobile version is the most convenient way to access the traditional Westports e-Terminal Plus website directly through smartphones across the globe. It consists of popular searches with real time information suitable for mobile users.

SMART CARD SECURITY SYSTEM

The adoption of this technology reduces the risk of loss and theft of containers, thus adding a greater level of assurance to cargo owners. It also enhances security in preventing document forgery as well as authenticates all entries and exits at the port.

PKNET

Port Klang Authority (PKA) is implementing the Port Klang Net (PKNet) initiative aiming at establishing a port and trade focused community system connecting key industry players under a common platform. This initiative is aimed to increased efficiency and cost reduction in Port Klang.

Westports is one of the players in the PKNet system where information on container movement in and out of the terminals are updated to the system for tracking purposes. Moving to the 4th quarter of the year, PKNet is enabling features for shippers to declare their containers VGM, forwarding agents to be able to apply for e-gate pass and hauliers will able to do pre arrival booking as an alternative mode to the terminal E- Terminal Plus system.

UCUSTOMS

The benefits of uCustoms are:

- Consistent operating procedures

- National Single Window

- Cost Savings on transactions

- Automation of manual processes

- Ease of information/Data sharing

- Enable working remotely

Westports has been selected to be part of the uCustoms pilot run which commenced on 30th September 2017. Westports will be integrating in phases with the uCustoms system starting with the Journey Declaration. The full integration with the uCustoms system should be completed within the 4th quarter of 2017.

E-CONVENTIONAL CARGO SYSTEM (E-CCS)

Based on requirements, our IT Team consolidated and upgraded the functions of NGCCS and CTCMS into a new single platform called E-Conventional Cargo System (E-CCS). The informative and user-friendly E-CCS was officially implemented on 1/4/2015. Besides automating manual processes which will improve their operational efficiency, the project also aims to meet our customers’ growing demands, ensure faster turnaround of dynamic changes and needs, while improving productivity monitoring.

This consolidated new E-CCS system controls all work processes in conventional cargo operations for Dry Bulk, Break Bulk, Liquid Bulk, Warehouse and RORO terminals. Its goals are to simplify and automate the conventional cargo processes from documentation, operation to billing.

WIRELESS

A typical process involves using handheld units to record the arrival of incoming containers as they are discharged from the vessel at the quayside; this system determined position is downloaded into vehicle mounted computers on the yard equipment; and this process is repeated for outgoing containers, when they are loaded onto another vessel, truck or rail.

E-BIDDING

Leveraging on this technology, Westports can increase efficacy of buying, sourcing, ordering, logistics tracking and payment processes.

ELECTRONIC DATA INTERCHANGE (EDI)

Westports is UN/EDIFACT compliant. Our e-Terminal and terminal operating systems like COSMOS and NGCCS allow the transfer of data files electronically such as:

- COPARN – Export booking

- BAPLIE and MOVINS – Stowage instruction and stowage plans

- COARRI – Loading/discharging container reports

- COPRAR – Loading/discharging order messages

- CODECO – Gate movement reports

- VESDEP – Terminal departure reports

- INVOIC – Invoice messages

- IFTDGN – Dangerous goods declarations

- CUSCAR – Customs manifests

Stars On Board